In metallurgy, hardness is defined as the ability of a material to resist plastic deformation. It is the property of a metal, which gives it the ability to resist being permanently deformed (bent, broken, or have its shape changed) when a load is applied. To measure the resistance of metal to plastic deformation is usually by indentation. The greater the hardness of the metal, the greater resistance it has to deformation.

In metallurgy, hardness is defined as the ability of a material to resist plastic deformation. It is the property of a metal, which gives it the ability to resist being permanently deformed (bent, broken, or have its shape changed) when a load is applied. To measure the resistance of metal to plastic deformation is usually by indentation. The greater the hardness of the metal, the greater resistance it has to deformation.

The common methods of hardness measurement on metallic materials provided by NUSATEK are:

- Rockwell Hardness Test

- Brinell Hardness Test

- Vickers Hardness Test

- Micro Vickers Hardness Test

Test Method/Specifications

- ASTM E384

- ASTM E92

- ASTM E10

- ASTM E18

Read More

Hardness Test

The hardness test gives an idea of the resistance to wear of the weld metal. This is important with respect to the components which have been built up and have to withstand abrasive wear. Hardness values can give information about the metallurgical changes caused by welding. In the case of premium and high carbon steels and cast iron, the heat affected zone or weld junction may become hard and brittle because of the formation of martensite. Hardness values in a welded joint are usually sensitive to such conditions of welding, as

- The process used.

- Heat input.

- Preheat or interpass temperature.

- Electrode composition

- Plate thickness.

Hardness values indicate whether the correct welding technique and pre and post heat treatments have been carried out. The hardness of welds is particularly important if the welds must be machined.

Methods of Hardness

Commonly used test methods for finding hardness are:

- Brinell Hardness Test

- Rockwell Hardness Test

- Vickers Pyramid Hardness Test

The welded specimen in whose case hardness is to be tested is ground, polished or polished and etched to show clearly the weld metal area. Hardness is determined on specific areas of interest, including the weld center line, face or root regions of the weld deposit, the heat affected zone and the base metal.

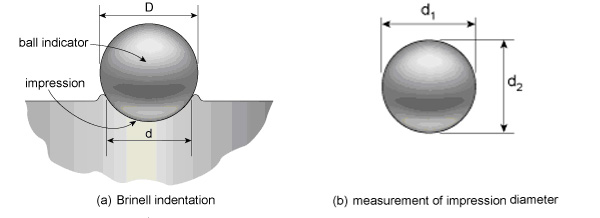

Brinell Hardness Test

It consists of pressing a hardened steel ball into a test specimen. According to ASTM specifications, a 10 mm diameter ball is used for the purpose. Lower loads are applied for measuring hardness of soft materials and vice versa.

Procedure for Brinell Hardness Testing

A specimen is placed on the anvil; the hand wheel is rotated so that the specimen along with the anvil moves up and contacts with the ball. The desired load is applied mechanically (by a gear driven screw) or hydraulically (by oil pressure) and the ball presses into the specimen.

The diameter of the indentation made in the specimen by the pressed ball is measured by the use of a micrometer microscope, having a transparent engraved scale in the field of view.

The indentation diameter is measured at two places at right angles to each other, and the average of the two readings is taken. The Brinell hardness number (BHN) which is the pressure per unit surface area of the indentation in kg per square metre, is calculated as follows:

W is load on indenter, kg D is diameter of steel ball, mm D is average measured diameter of indentation, mm

Figure 1 Vickers Hardness Test

The Vickers hardness test operates on similar principles to the Brinell test, the major difference being the use of a square based pyramidal diamond indentor rather than a hardened steel ball. Also, unlike the Brinell test, the depth of the impression does not affect the accuracy of the reading so the P/D2 ratio is not important. The diamond does not deform at high loads so the results on very hard materials are more reliable. The load may range from 1 to 120 \

and is applied for between 10 and 15 seconds.

The basic principles of operation of the Vickers hardness test are illustrated in Figure 2 where it can be seen that the load is applied to the indentor by a simple weighted lever. In older machines, an oil filled dash pot is used as a timing mechanism - on more modern equipment this is done electronically.

As illustrated in Figure 2 (b) two diagonals, d1 and d2, are measured, averaged and the surface area calculated then divided into the load applied. As with the Brinell test the diagonal measurement is converted to a hardness figure by referring to a set of tables. The hardness may be reported as Vickers Hardness number (VHN), Diamond Pyramid Number (DPN) or, most commonly, Hvxx where 'xx' represents the load used during the test.

Figure 2 As mentioned earlier, the Vickers indentation is smaller than the Brinell impression and thus far smaller areas can be tested, making it possible to carry out a survey across a welded joint, including individual runs and the heat affected zones. The small impression also means that the surface must be flat and perpendicular to the indentor and should have a better than 300 grit finish.

Figure 3 Rockwell Hardness Testing - Rockwell hardness testing differs from Brinell testing in that the indenters and the loads are smaller and therefore the resulting indentation on the specimen is smaller and shallower. Rockwell testing is suitable for materials having hardness beyond the scope of Brinell testing.

Rockwell testing is faster as compared to Brinell testing because the diameter of indentation need not be measured; and the Rockwell machine gives arbitrary direct reading. Unlike Brinell testing, Rockwell testing needs no surface preparation (polishing, etc.) of the specimen whose hardness is to be measured.

Procedure For Measuring Hardness

- Test piece is placed upon the machine. The machine dial does not show any reading.

- Hand wheel is turned, thereby raising the test piece up against the steel ball indentor till the needle on the dial reads zero. This applies minor load.

- Major load is applied by pressing the crank provided on the righthand side of the machine (not shown).

- Crank is turned in the reverse direction thereby withdrawing major load but leaving minor load applied.

- Hand wheel is rotated and the test piece is lowered.

At this stage, the hardness of the test piece material can be directly read from the dial scale. There are two scales on a Rockwell testing machine, i.e. 'B' scale and 'C' scale. B scale uses a steel ball indentor whereas a diamond cone penetrator is employed for measuring hardness on C scale. B scale is for testing materials of medium hardness such as low and medium carbon steels in the annealed condition. The working range of this scale is from 0 to 100. C scale is used for testing materials harder than B 100. C scale is commonly used for testing the hardness of alloy cast irons. In Rockwell hardness testing, the minor load for all cases is 10 kg whereas major loads for scales C and Bare 150 and 100 kg respectively (including minor load).